Home » Maritime Projects » Ship Sizing Calculator » About

ABOUT

SHIP SIZING

CALCULATOR

This calculator estimates ship dimensions and cargo capacity when powered by various alternative fuels. This is a useful tool for ship sizing during the design stage. By using this calculator, maritime stakeholders and shipowners can estimate the feasibility to replace conventional Heavy Fuel Oil (HFO) with low- or zero-carbon fuels.

USER-DEFINED PARAMETERS

A total of 8 inputs need to be defined under “MY SHIP” user-defined parameters:

- Ship type, fuel type, energy converter & max rated power (kW), and cargo type can be chosen from a drop-down list. There are three options for energy converters which are internal combustion engine (ICE), electrical motor (EM) and fuel cell in combination with electrical motor (PEMFC & EM). Users can select a suitable energy converter with a power rating larger than their ship’s requirement and adjust the power setting (%) to obtain the average rated power of the ship.

- Ship deadweight capacity (tons or DWT), voyage distance/trip (n.m.), and power setting (%) can be adjusted using the slider.

- A checkbox for onboard carbon capture and storage (CCS) installation can be checked if CCS installation is desired – CCS with a 90% carbon capture rate by default will be included if this box is checked.

- “Click to Reset” will reset the parameters.

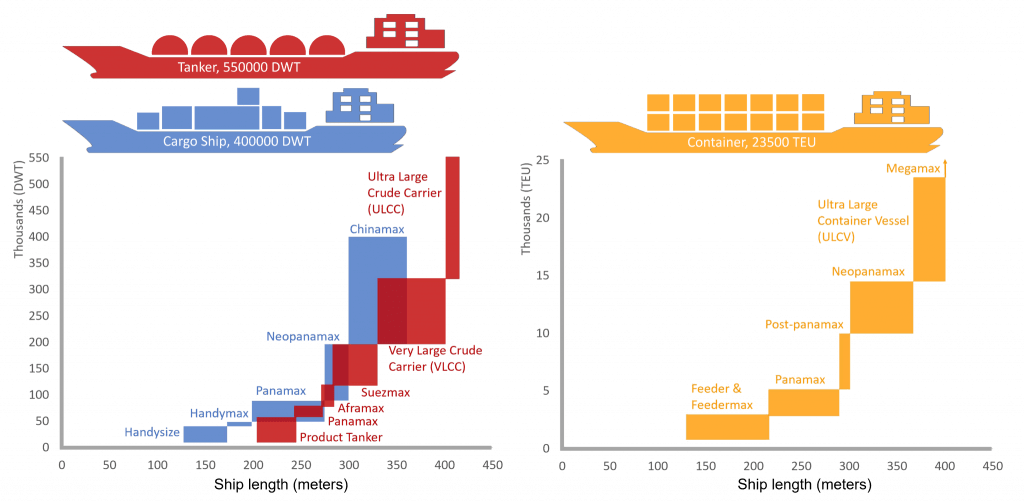

Three types of ships are included which are tanker, cargo ship and container. The figure below shows the ship length (meters) of various types of ships and their categories. Generally, tanker and cargo ship are categorised based on ship deadweight, whereas container is defined based on the ship cargo capacity in twenty-foot equivalent units (TEU).

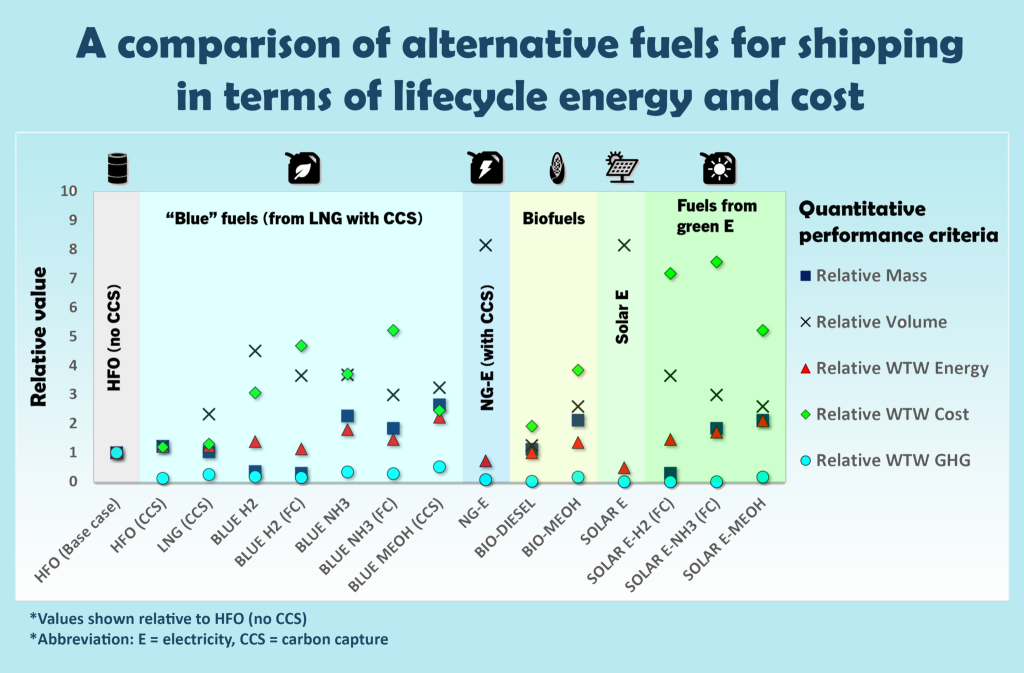

As more alternative fuels are being considered for replacement of the conventional Heavy Fuel Oil (HFO), a detailed assessment was published to compare the various alternative fuel pathways for instance installation of carbon capture technology (HFO(CCS)), liquefied natural gas (LNG), liquefied natural gas with CCS installation (LNG(CCS)), hydrogen, ammonia, and methanol produced from fossil fuel primary energy (BLUE H2, BLUE NH3, BLUE MEOH), electricity produced from natural gas with carbon capture during fuel production (NG-E), biodiesel (BIO-DIESEL), and bio-methanol (BIO-MEOH). As hydrogen and ammonia can be powered by both dual fuel engine (ICE) and fuel cell (FC), users need to select the fuel type and their choice of energy converter.

Ships are generally not operated with 100% load; hence users can adjust the engine loading between 0-100%.

Users can check or un-check this parameter. This calculator assumes that an Amine-based post-combustion CCS with a 90% carbon capture efficiency is installed onboard when this parameter is checked. As onboard carbon capture (CCS) is a potential carbon reduction measure for ships powered by fossil fuels such as HFO, LNG, and MEOH, this input is included to study the effect of CCS installation on ship performance.

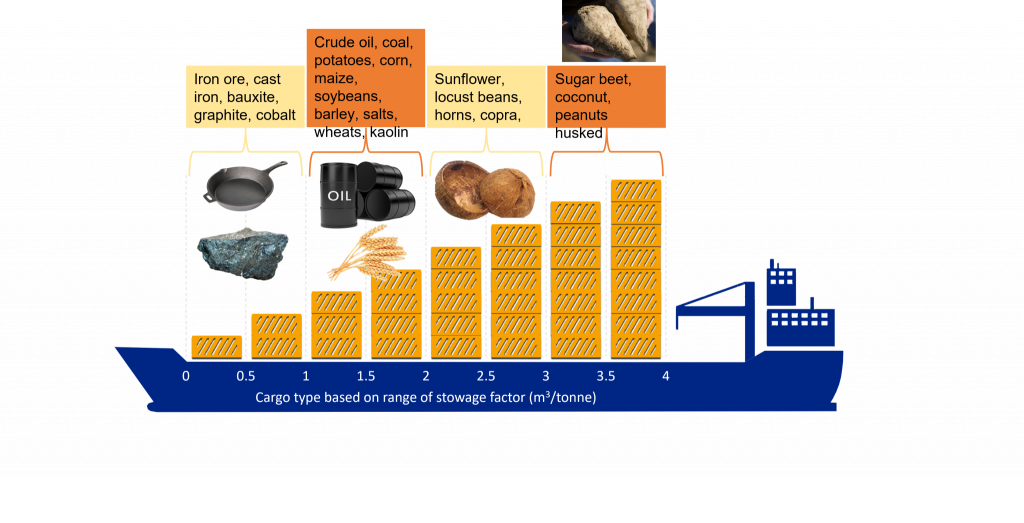

The quantity of cargoes that can be carried by a ship varies with the type of cargoes as they have varying densities and stowage factors. The figure below shows the general types of cargoes and their stowage factor in unit cubic meter per tons (m3/tons).

RESULTS OF ASSESSMENT (SHIP SIZING)

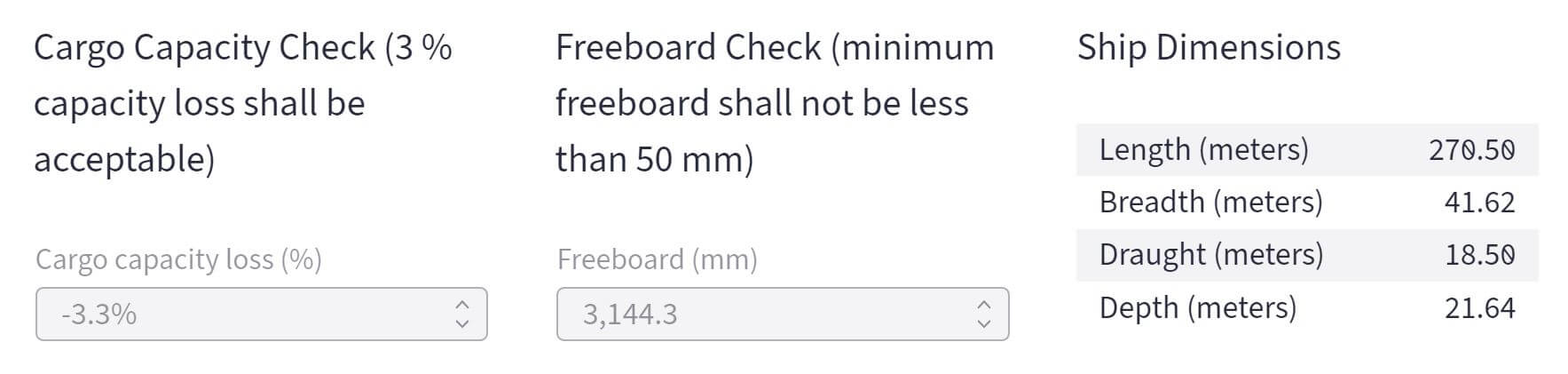

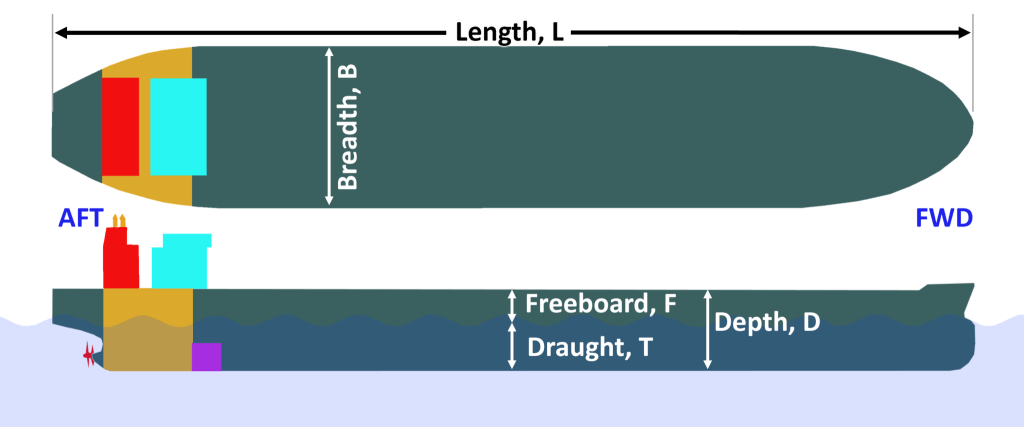

Ship Sizing Calculator performs cargo capacity and freeboard checks for the user-defined ship to ensure that the cargo loss is within an acceptable range – this is generally 3% but it is subject to the user’s acceptance. This calculator is also useful for quick sizing of ships to estimate ship length (L), breadth (B), draught (T) and depth (D) based on the user’s inputs.

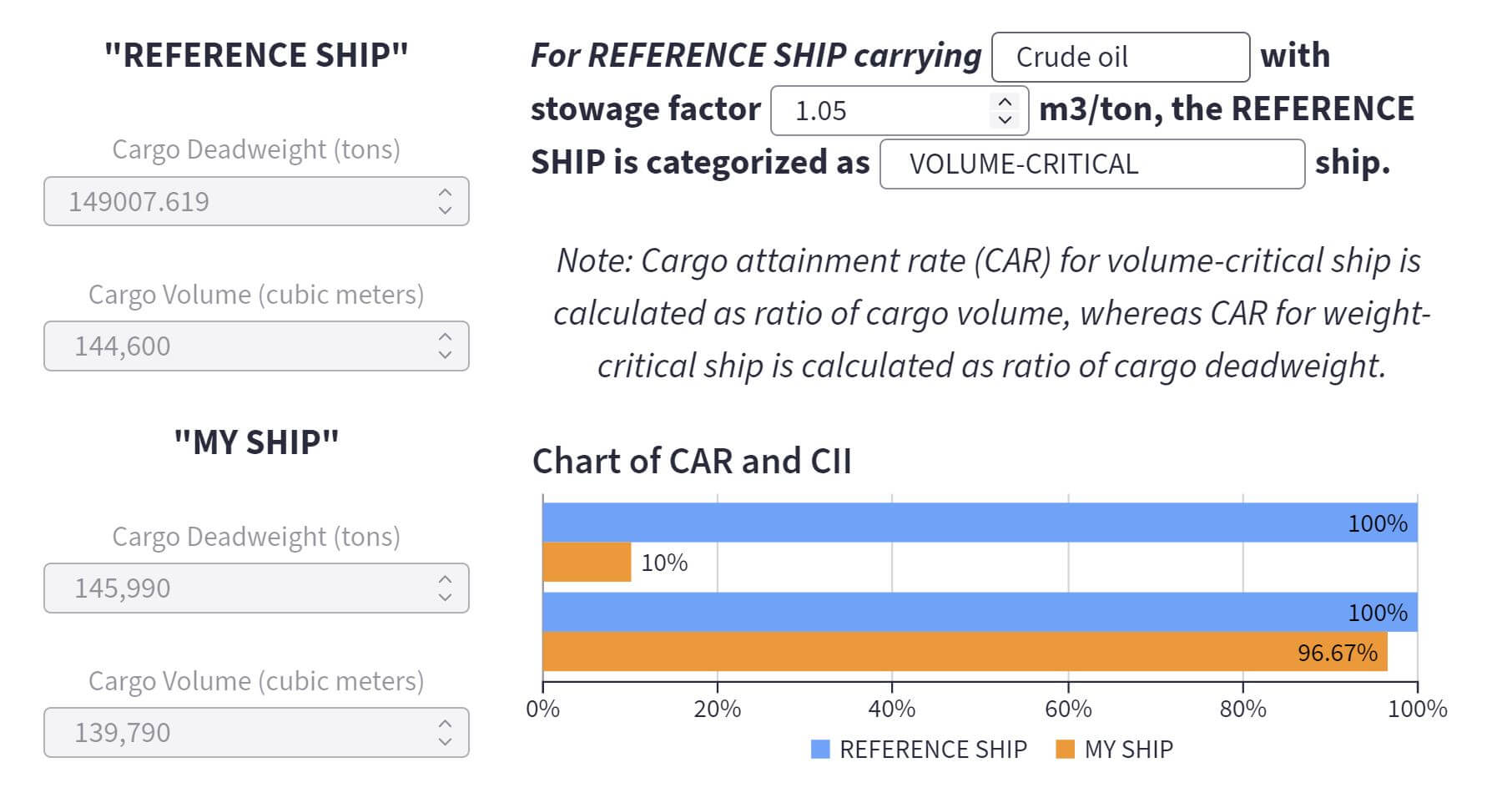

Cargo Attainment Loss (CAL) is a ship performance indicator which is defined as the difference in cargo attainment rate (CAR) between the user-defined ship and reference ship, with the CAR for reference ship fixed at 100% CAR by default. Please note that the “REFERENCE SHIP” is a ship with the same design parameters as “MY SHIP”, except for the fuel type and energy converter which is fixed as HFO as and ICE respectively.

Explanation of the results obtained:

- Negative CAL: The ship can carry less cargo than the reference ship.

- Positive CAL: The ship can carry more cargo than the reference ship.

In general, negative 3% of CAL is acceptable.

Freeboard is the distance from the waterline to the upper deck of a ship. As a rule of thumb, the freeboard of any ship shall not be lesser than 50 mm. Reference can be made to Regulation 28 – Freeboard tables under Chapter III – Freeboard for the tabular freeboard of ships of different lengths. In general, the longer the ship length, the larger the required freeboard height.

Explanation of the results obtained:

- Freeboard < 50 mm: The ship needs to be re-designed as the calculated freeboard is lesser than the minimum freeboard requirement.

- Freeboard > 50 mm: The ship is well-designed.

For different types of ships with the same deadweight, ship dimensions will differ due to the variation of deadweight coefficient values. The typical values are obtained from “Ship Design and Performance for Masters and Mates” which was written by experienced marine engineering consultants. A variation in deadweight coefficient values will result in varied ship displacement, which is a function of ship length (L), breadth (B), draught (T), and ship block coefficient (Cb). Hence, ship dimensions will change with displacement and are estimated based on deadweight and ship type input.

RESULTS OF ASSESSMENT (CARGO CAPACITY)

In terms of cargo capacity, the calculator determines the cargo deadweight and cargo volume of “MY SHIP” and “REFERENCE SHIP” based on user-defined parameters. Based on the calculated cargo deadweight, volume, and type for the “REFERENCE SHIP”, the ship is categorised as a Weight-critical or Volume-critical ship.

For example, for the reference ship carrying crude oil with a stowage factor of 1.05 m3/ton, the ship is volume-critical; however, the same ship carrying iron ore with a stowage factor of 0.74 m3/ton, the ship is weight-critical due to the high-density cargo which requires more cargo deadweight allowance. Users can try to select different cargo types to visualize their impact on ship category and the cargo attainment rate (CAR).

The main purpose of replacing HFO with low- and zero-carbon fuel is to reduce the carbon intensity of ships. Hence, the carbon intensity indicator (CII) of both “REFERENCE SHIP” and “MY SHIP” is plotted on the same chart for the purpose of comparison.